Part 1: Understanding Diesel Engine, Its Working Principle and Key Components

During power outages, a diesel generator guarantees that power continues to be supplied to a property. Consequently, diesel generators are a vital machine in property management. In these scenarios, a malfunctioning diesel generator can hurt just about any operation, even costing businesses substantial sums of money.

To explain diesel generators more clearly, I will be presenting an 8 part series that will touch on the nine topics:

- Diesel Engine and its Working Principles

- Alternator and its Working Principles, Key Components

- Diesel Generator Subsystems – Starting System, Lubrication System, Fuel System, Cooling System, and Air System

- Diesel Generator Maintenance – A, B, C, D Checks

- Diesel Generator Standard Operating Procedures (SOPs), Diesel Generator Do’s and Don’ts, Diesel Generator Efficiency Calculations

- Diesel Generator Interview Questions & Answers.

This first installment will focus on the Diesel Engine, its working principles, and key components to aid in fully grasping more complicated aspects about diesel generators. So let's begin!

What is a Diesel Generator?

A Diesel Generator (DG) is a powerful and compact machine that converts mechanical energy into electrical energy. It consists of a diesel engine coupled with an alternator to generate electricity.

How Does a Diesel Generator Work?

In a diesel generator, air is drawn into the cylinder and compressed to a high ratio of 14:1 to 25:1. This compression increases the air temperature to about 700–900°C. Then, a precise amount of diesel fuel is injected into the cylinder, where it spontaneously ignites due to the high temperature. The energy released from combustion pushes the piston, producing rotational mechanical energy, which is transmitted to the alternator to generate electricity.The alternator works on Faraday’s Law of Electromagnetic Induction, converting kinetic energy into electrical energy, which is then supplied to the load.

Major Parts of a Diesel Generator A Diesel Generator consists of several essential parts that work together to produce electricity:

- Diesel Engine – The main power source that converts fuel into mechanical energy.

- Alternator – Converts mechanical energy into electrical energy.

- Fuel Tank – Stores the diesel required for operation.

- Auxiliary Alternator – Helps in providing power to auxiliary components.

- Starter Motor – Used to start the diesel engine.

- Battery – Supplies initial power to start the generator.

- Control Panel – Monitors and controls the generator's operation.

- Acoustic Enclosure (Canopy) – Reduces noise and protects the generator from external elements.

Diesel Engine Working Principle The diesel engine operates on a four stroke cycle, which includes the suction stroke, compression stroke, power stroke, and exhaust stroke. These four stages work in a continuous sequence to generate mechanical energy, which is then converted into electrical power by the alternator in a diesel generator.

a. Suction/Induction StrokeDuring the suction stroke, the intake valve remains open while the exhaust valve remains closed. As the piston moves downward from Top Dead Center (TDC) to Bottom Dead Center (BDC), a partial vacuum is created inside the cylinder. This pressure difference causes fresh air to rush into the cylinder through the intake valve. Unlike gasoline engines, diesel engines do not mix fuel with air at this stage, only air is drawn in. This fresh charge of air is crucial for the subsequent combustion process, ensuring efficient fuel ignition and power generation.

b. Compression Stroke

Once the piston reaches BDC, the intake valve closes, and the piston begins to move upward from BDC to TDC. Both the intake and exhaust valves remain closed during this stroke, allowing the air inside the cylinder to be compressed. As the piston compresses the air, the pressure inside the cylinder increases significantly, reaching up to 25 bar, while the temperature rises above 560°C. At this high temperature, diesel fuel is injected into the cylinder by the fuel injector. Since the compressed air is already at a high temperature, the diesel fuel ignites spontaneously upon injection, leading to a controlled explosion. This process releases a large amount of energy, preparing for the next stage, the power stroke.

The power stroke is the most critical phase of the engine cycle, as it generates the force that drives the engine. As the fuel air mixture combusts, it produces high pressure gases that force the piston downward from TDC to BDC. This downward movement is known as “useful work done” because it drives the crankshaft, converting the linear motion of the piston into rotational motion. The connecting rod plays a crucial role in transferring this energy from the piston to the crankshaft, which ultimately powers the alternator in a diesel generator. Since both intake and exhaust valves remain closed during this phase, the maximum pressure is utilized for efficient power generation.

d. Exhaust Stroke

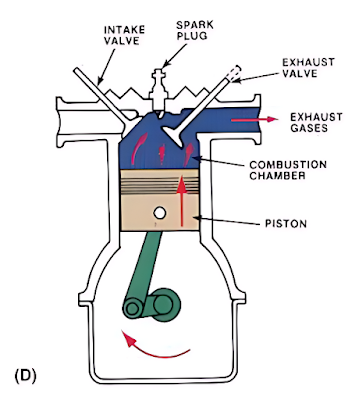

After completing the power stroke, the burned gases inside the cylinder must be expelled to make room for the next cycle. During the exhaust stroke, the exhaust valve opens while the intake valve remains closed. The piston moves back upward from BDC to TDC, pushing the burned gases out of the cylinder through the exhaust valve. These gases are then expelled into the atmosphere through the exhaust system. Once the piston reaches TDC, the exhaust valve closes, and the cycle repeats from the suction stroke.

This four stroke cycle repeats continuously in a diesel engine, ensuring a steady supply of mechanical power, which is then converted into electrical energy in a diesel generator. The efficiency of this process makes diesel engines highly reliable and suitable for various applications, from industrial and commercial use to emergency backup power systems.

Key Components of a Diesel Engine

A diesel engine consists of several critical components that work together to convert fuel into mechanical energy efficiently. Each component has a specific function that ensures optimal performance, durability, and reliability. Below is a detailed breakdown of the key parts of a diesel engine and their roles in power generation.

Turbocharger

The turbocharger is an essential component designed to increase the engine’s power output without significantly increasing its size or weight. It operates by utilizing exhaust gases to force more air into the combustion chamber, thereby improving fuel combustion efficiency. The turbocharger consists of two main sections: the turbine and the compressor.

The turbine, which includes a turbine wheel and housing, directs the flow of exhaust gases, causing the wheel to spin. This rotational force is transferred via a forged steel shaft to the compressor, which consists of a compressor wheel and housing. The compressor increases the density of the incoming air, ensuring more oxygen reaches the combustion chamber. This enhanced airflow results in better fuel combustion, increasing engine efficiency and power output.

Cylinder Head

The cylinder head is a crucial structural component that seals the top of the engine cylinder, forming an enclosed space for compressed air and fuel combustion. It houses several important elements, including inlet and exhaust valves that regulate air intake and gas expulsion, a fuel injection valve that sprays fuel into the combustion chamber, and cooling chambers that circulate coolant to prevent overheating. The cylinder head plays a vital role in maintaining compression, improving combustion efficiency, and ensuring effective heat dissipation.

Driving Mechanism

The driving mechanism is responsible for converting the linear motion of the pistons into rotational motion, which ultimately powers the generator. The crankshaft is at the core of this system, rotating as it receives energy from the pistons via connecting rods. To maintain balance and reduce vibrations, balance weights are incorporated to offset the rotational forces. Additionally, the camshaft, which operates through a gear driven system, plays a key role in synchronizing the opening and closing of inlet and exhaust valves. It achieves this through the use of push rods and rocker arms, ensuring precise valve timing for optimal combustion.

Fuel Pump, Injection Pump, and Fuel System

The fuel system is responsible for delivering diesel fuel from the storage tank to the combustion chamber efficiently. The fuel pump first transports fuel from the tank to the injection pump through a filtration system to remove impurities. The injection pump then precisely meters and delivers fuel to the injection nozzles, which atomize the fuel into fine droplets for efficient mixing with compressed air. A fuel feed pump continuously circulates excess fuel, returning the unused portion to the tank through an overflow valve. This system ensures precise fuel delivery, optimizing combustion and engine performance.

Lubrication System (Lube Pump and System)

Proper lubrication is essential for reducing friction, preventing wear and tear, and dissipating heat generated during engine operation. The lube oil pump draws oil from the oil pan and distributes it to critical engine components, such as the crankshaft, camshaft, and pistons. Before reaching these parts, the oil passes through an oil cooler to regulate its temperature and an oil filter to remove contaminants. This system ensures smooth engine operation, extends the lifespan of components, and minimizes maintenance requirements.

Radiator and Cooling System

Since only a portion of the fuel’s thermal energy is converted into mechanical power, effective cooling is necessary to prevent overheating and ensure efficient engine performance. The coolant, typically a mixture of water and antifreeze, circulates around the combustion chamber walls, absorbing excess heat. The radiator and fan then work together to dissipate this absorbed heat into the atmosphere. By maintaining optimal engine temperature, the cooling system prevents thermal damage and enhances overall reliability.

Electronic Control Panel (ECP)

The Electronic Control Panel (ECP) plays a critical role in monitoring and regulating the engine’s performance. A magnetic pickup sensor detects the engine’s speed by reading signals from the flywheel ring gear and generates an AC voltage proportional to the engine's RPM. Based on these readings, an actuator adjusts the fuel supply to maintain a stable engine speed. The ECP continuously compares the actual engine speed with a preset reference, such as 1500 RPM, and fine tunes the actuator's current to ensure smooth and efficient operation. This automated control system enhances fuel efficiency, prevents engine overload, and enables precise speed regulation.

Exhaust System

The exhaust system is responsible for safely expelling the combustion gases produced during engine operation. An exhaust bellow connects the engine to the DG silencer, ensuring a smooth flow of exhaust gases. The muffler significantly reduces engine noise, while the exhaust extension pipe ensures that gases are expelled safely into the atmosphere. By efficiently managing exhaust emissions, this system contributes to environmental compliance and enhances operational safety.

Fuel Tank

The fuel tank serves as the storage reservoir for the diesel required to operate the generator. It is equipped with a Fuel Level Float, which continuously monitors the fuel level and sends real time data to the gauge. Additionally, a Fuel Level Sensor is integrated into the system to alert the engine safety unit when the fuel level is critically low. In such cases, alarms are triggered, and in extreme situations, the system can initiate an automatic shutdown to prevent engine damage due to fuel starvation.

Final Thoughts

Diesel generators are indispensable in property management and industrial applications, ensuring reliable power supply in critical situations. Understanding the diesel engine’s working principles and key components provides a strong foundation for efficient operation, maintenance, and troubleshooting. This first part of our 8 part Diesel Generator Insights series has given you a deep dive into the engine's mechanics, from air intake to power generation.

In the next installment, we will explore Alternators, their Working Principles, and Key Components, which play a crucial role in converting mechanical energy into electrical power. Stay tuned!

I’d love to hear your thoughts, feel free to comment below with any questions, feedback, or topics you'd like us to cover in upcoming parts. If you found this article helpful, share it with others who might benefit from it.

Disclaimer

This article is for educational purposes only and is based on information compiled from various online sources. While every effort has been made to ensure accuracy, readers should consult manufacturer guidelines or professional experts for specific operational and maintenance requirements.

See you in Part 2!

Comments

Post a Comment